D-BRAIN

Detection Brain

Our Detection Brain helps enterprises digitally transform their inspection processes by processing camera feeds and various types of image data all at a faster and more accurate rate than could ever be achieved by human inspections alone.

D-Brain Use Cases

Image Defect Detection

Our quality defect standards are customer-specific and encompass product quality grading (Good/Bad/Faulty) as well as defect classifications, such as Scratch, Oxidation, Corrosion, Nick, and Missing parts. Mindtrace offers support for various imaging formats, including RGB, X-RAY, and DCOM, enabling precise localization of defective regions.

Point Cloud Defect Detection

Defects as minuscule as 2-3mm, such as corrosion and cracking, can be effectively detected and identified within point cloud images.

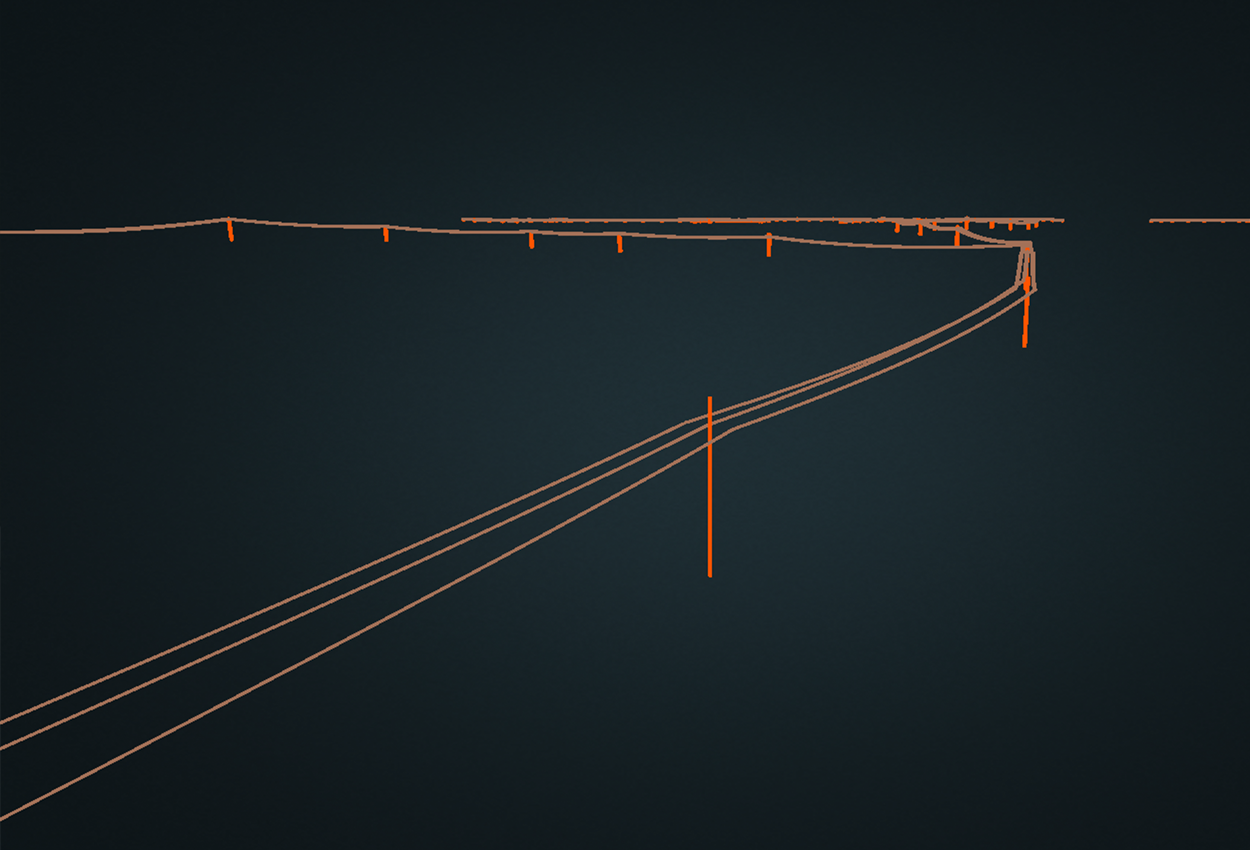

Vectorization Capabilites

Our D-Brain rapidly generates 2D and 3D vectors, seamlessly accommodating multiple data formats. Its capabilities are extensive, covering wire conflation, wire type identification, wire sagging simulation, the delineation of building and tree boundaries, centerline simulation, and the automated construction of complete network graphs.

Mindtrace Case Studies

Curious to see how C-Brain has been used in conjunction with our other AI Brains to drive real-world results? Check out one of our industry case studies below!