CASE STUDY

Digital Watches

A globally-renowned electronics company sought our expertise to elevate their defect detection capabilities within their digital watches, analyzing for defects on the watch faces.

Mindtrace was selected to create an industry-leading AI model that seamlessly integrates into their existing model backbone, reducing disruption while revolutionizing their manual quality assessment procedures.

Challenges

- Under 300 available training data images

- Unlabelled training data

- Images contain high levels of noise

Step 1 - Model Training

During the training phase, Mindtrace's Brain-Sense™ Platform successfully processed 300 training images utilizing few-shot learning due to the limited information present in the dataset.

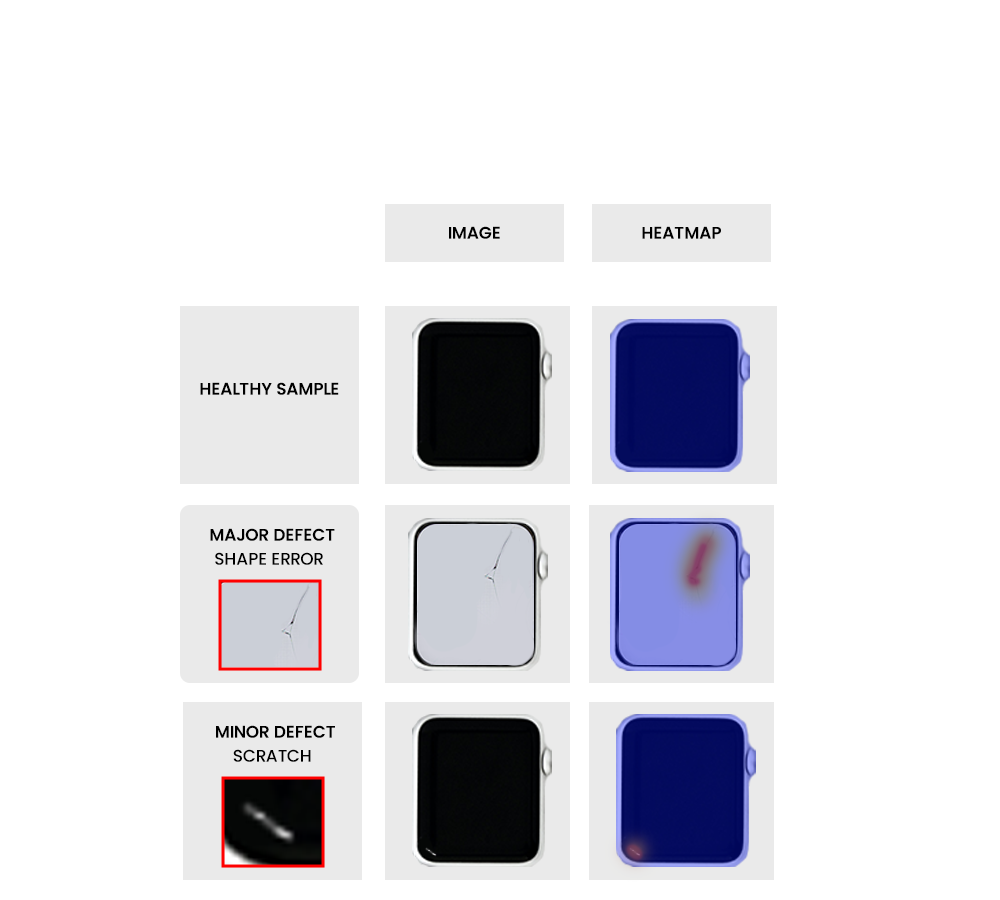

Step 2 - Model Testing

After the training phase was complete, the model was tested on further data samples, achieving a 97% defect detection rate.

Outcome

Despite the constraints of a limited dataset and the presence of noise, Mindtrace’s Brain-Sense™ platform effectively developed a bespoke AI solution that achieved a 97% defect detection rate within the training data.

Furthermore, this solution seamlessly integrates into their existing model backbone, with deployment options available for on-premises, cloud, or edge devices, ensuring minimal disruption.

AI Brains Used

Detection

Identifies defect types, severity & location.

Classification

Object identification & classification.

Analytics

Generates insights & recommendations.

Learning Samples

Defects Detected

Delivery Time