CASE STUDY

Manufacturing

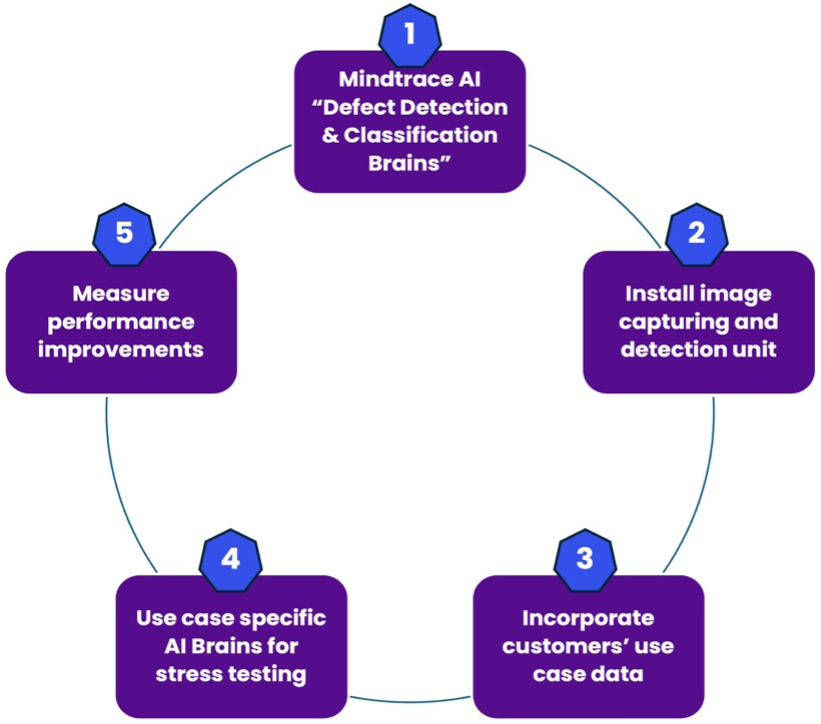

As precision parts manufacturers are continually embracing new ways and methods to squeeze out last mile efficiency gains that will positively impact EBITDA as well as building a set of AI brain libraries that are fully battle tested for enterprise specific use cases.

Mindtrace’s Brain-Sense™ solution is not only fulfilling performance thresholds set by the enterprises, but also exceeding expectations in terms of accuracy, consistency, and scalability.

Challenges

- 1. Bottleneck in manufacturing throughput – slow finished parts inspection process

- 2. Associated labor costs

- 3. Unreliable operator quality inspection process

- 4. Lack of audit trails on pass versus fail inspection results

Outcome

By leveraging Mindtrace’s few-short learning capabilities, the solution can surpass the defect detection accuracy of human operators with around 10 samples, while classical AI often requires thousands to reach that accuracy benchmark.

AI Brains Used

Classification

Object identification & classification.

Detection

Identifies defect types, severity & location.

Analytics

Generates insights & recommendations.

F1 score achieved using proprietary AI & ML

Reduction in time to inspect parts for defects

Average # of images with defects present needed to match human QA inspector performance