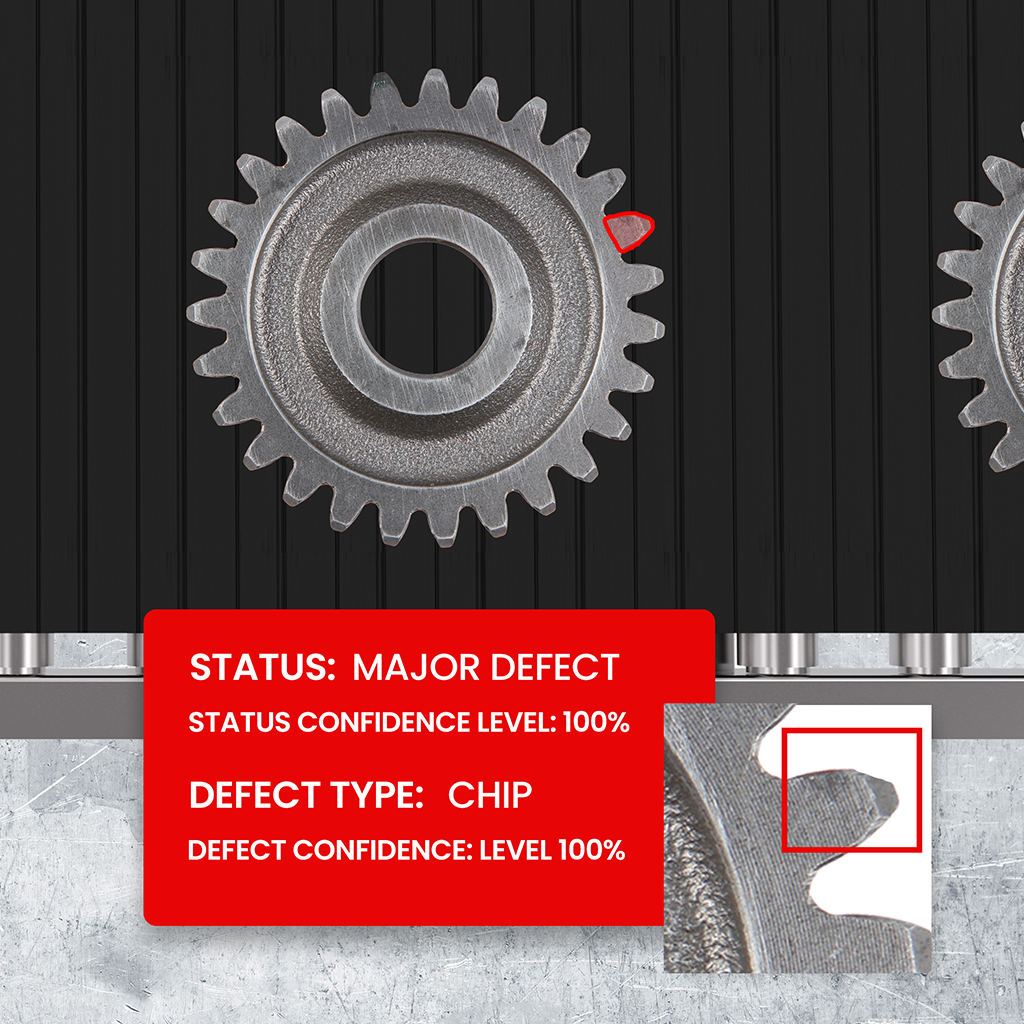

Implement AI-driven defect detection to automate quality checks

Improve both defect detection accuracy and throughput by integrating Mindtrace’s exclusive AI software with readily available hardware, enhancing your team’s quality control capabilities.

- Supports over 100 defect types

- Recognizes most imaging formats, including RGB, X-RAY and DCOM to localize defective regions

- Trained to flag all types of finished and unfinished goods of products as having an anomaly as well as classifying defect types with high accuracy

Challenges with manual Precision Manufacturing

Data Limitations

Traditional AI Solutions require thousands of labelled data samples to train a model, making it a time-consuming challenge to implement AI.

Mindtrace’s Solution

In many cases, Mindtrace AI Brains can be trained to accurately detect defects and anomalies with as few as 10 images.

Inconsistent Inspection Processes

Manual defect and anomaly detection are prone to human error as repetitive visual inspections lead to operator fatigue and increased likelihood of errors.

Mindtrace’s Solution

By augmenting your inspection process to include a Mindtrace AI Brain, you’ll have a solution that thrives on repetition.

Labor Risks

Vulnerability to labor shortages and the risk of knowledge depletion due to high employee turnover and shortage of qualified replacements.

Mindtrace’s Solution

By installing an AI Brain as part of your Defect Detection process, you can reduce training times, and in some cases, headcount.

TYPICAL ENTERPRISE PROJECT TIMELINE

A complete Precision Defect Detection Solution deployed within weeks, not months

01

Briefing and Data Normalization

We work closely with your team to curate and normalize the correct dataset.

Average Time: 1 Week

02

Brain Development

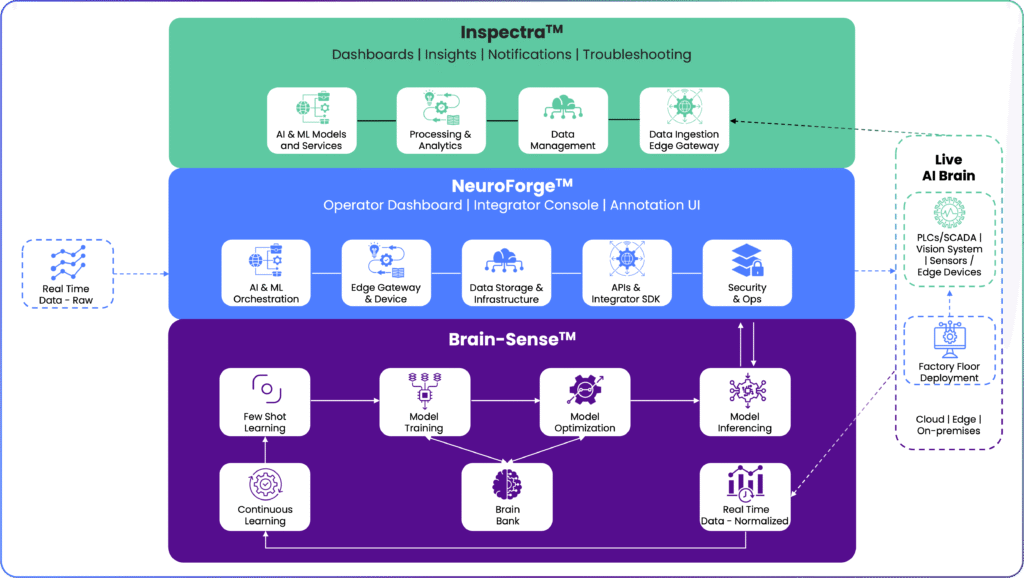

Utilizing our Brain-Sense™ Platform to develop your AI Brain.

Average Time: 3 Weeks

03

Brain Deployment

Your AI Brain is deployed using dedicated Cloud, servers or edge devices.

Average Time: 1 Day

04

Post-Deployment Monitoring

The brain continuously improves, learning from tasks and knowledge sharing.

Average Time: Ongoing