Mindtrace NeuroForge™

Integration-Ready, Custom Application

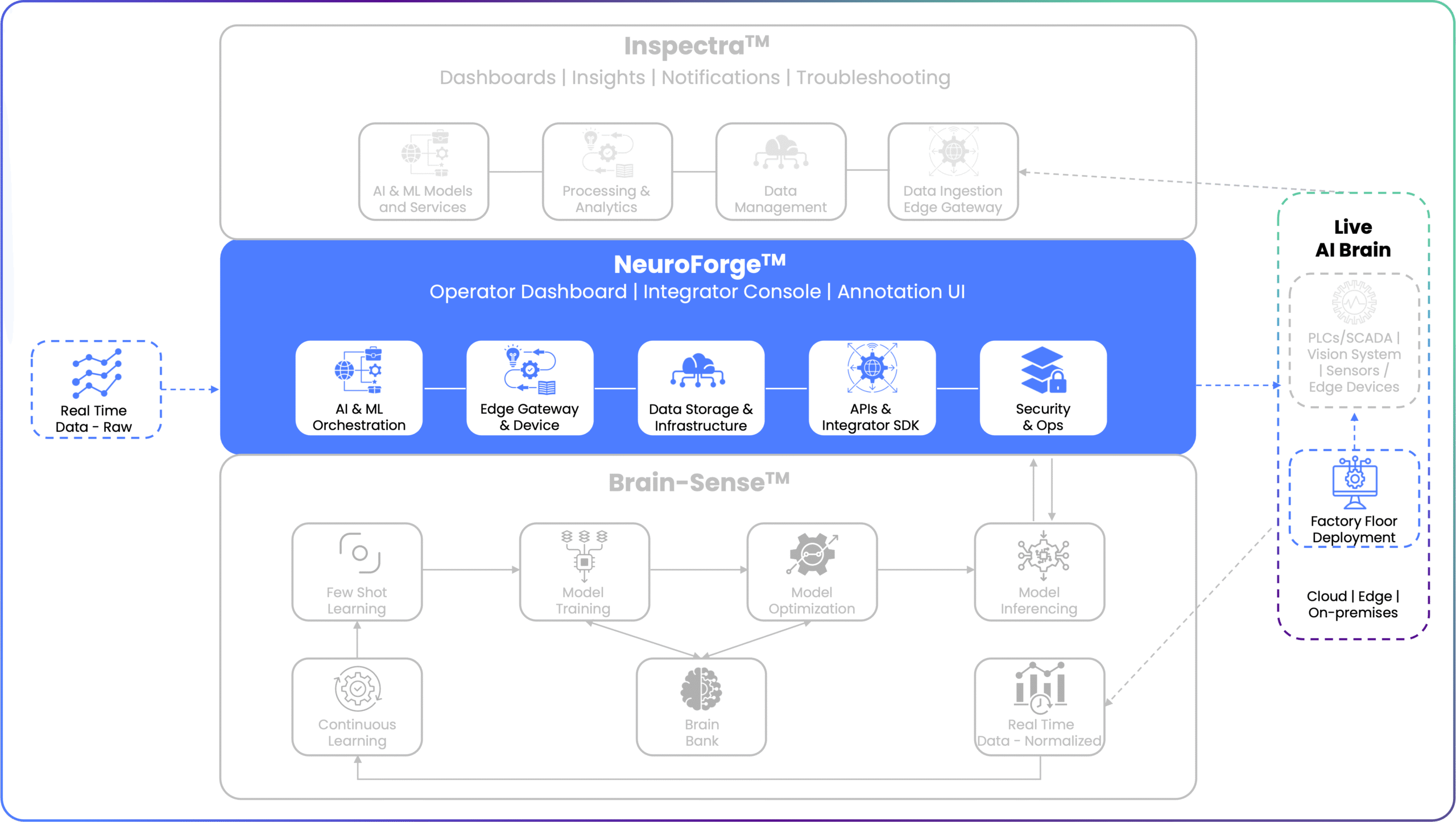

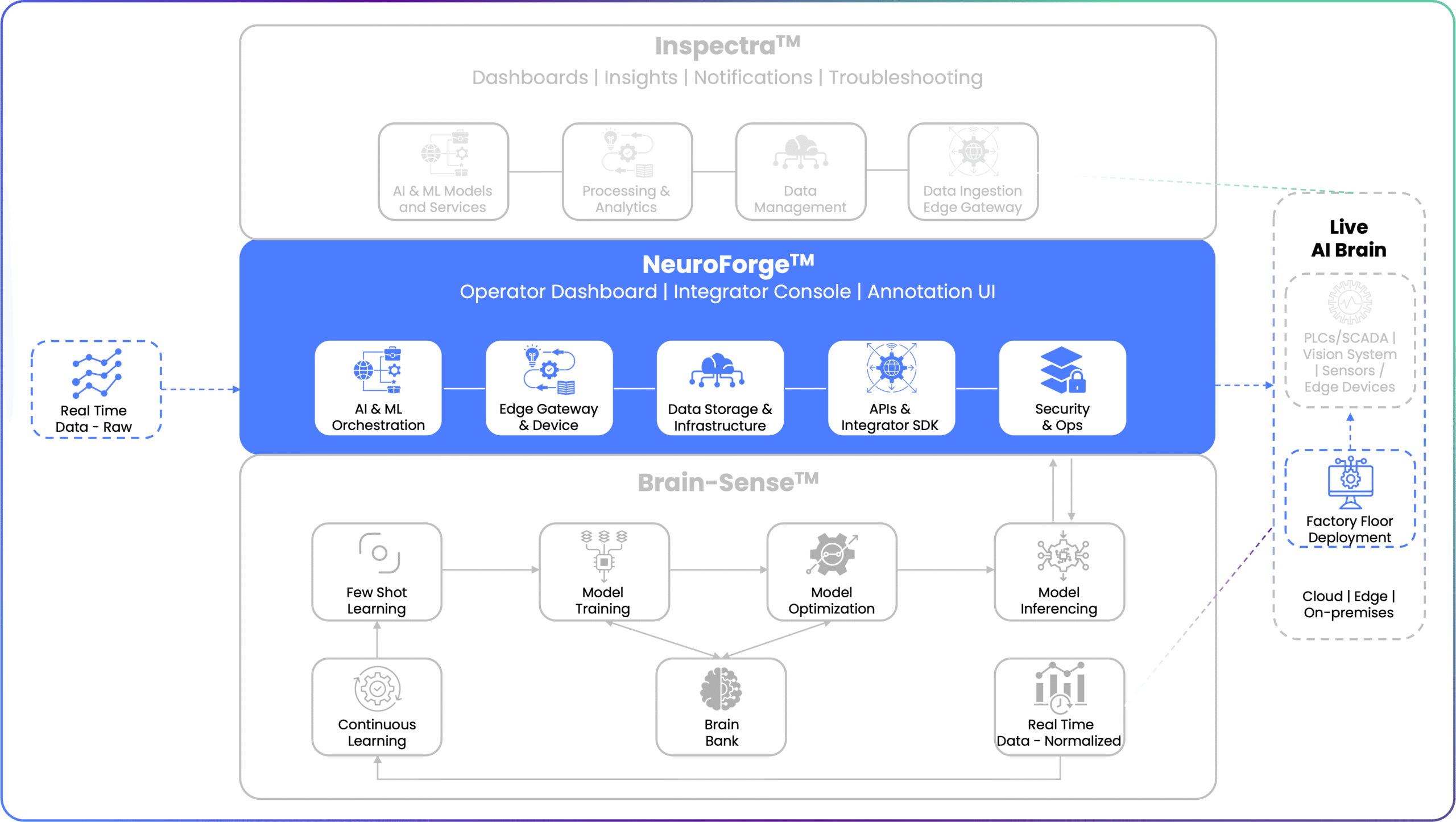

NeuroForge™ is the integration platform for Brain-Sense™. It provides a set of tools and gateways that embed Brain-Sense™ AI defect detection into manufacturers’ existing production cells, workflows, data pipelines and production-specific requirements.

NeuroForge™ transforms smart manufacturing technology into operational reality — bridging the gap between AI research and the factory floor. NeuroForge™ enables secure, scalable, and efficient deployment, reducing risk and accelerating ROI.

Mindtrace NeuroForge™

Integration-Ready, Custom Application

NeuroForge™ is the integration platform for Brain-Sense™. It provides a set of tools and gateways that embed Brain-Sense™ AI defect detection into manufacturers’ existing production cells, workflows, data pipelines and production-specific requirements.

NeuroForge™ transforms smart manufacturing technology into operational reality — bridging the gap between AI research and the factory floor. NeuroForge™ enables secure, scalable, and efficient deployment, reducing risk and accelerating ROI.

With Mindtrace

Fewer Images

Cost Reduction

Gage R&R Score

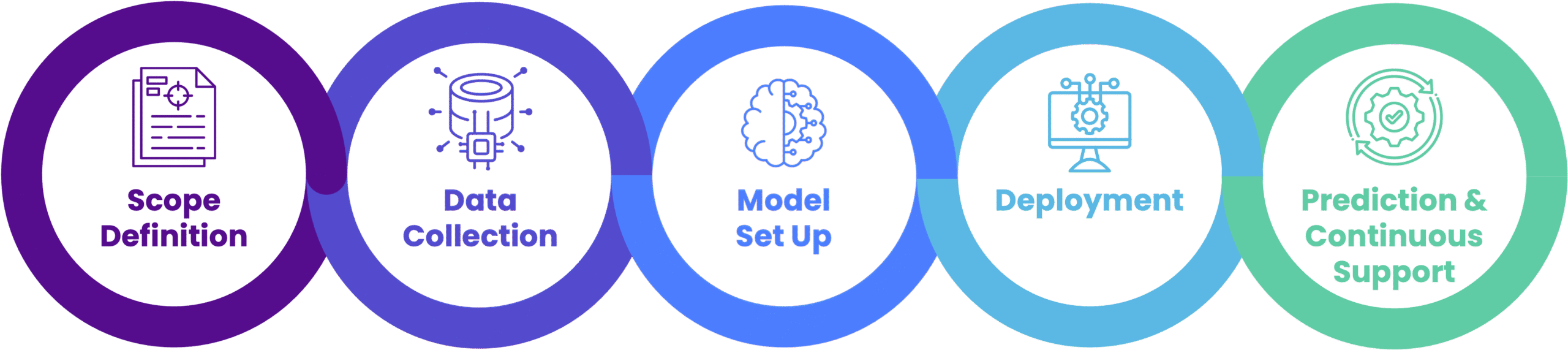

How NeuroForge™ Works

Scope Definition

Data Collection

Model Setup

Deployment

Prediction & Continuous Improvement

Scope Definition

Data Collection

Model Setup

Deployment

Prediction & Continuous Improvement

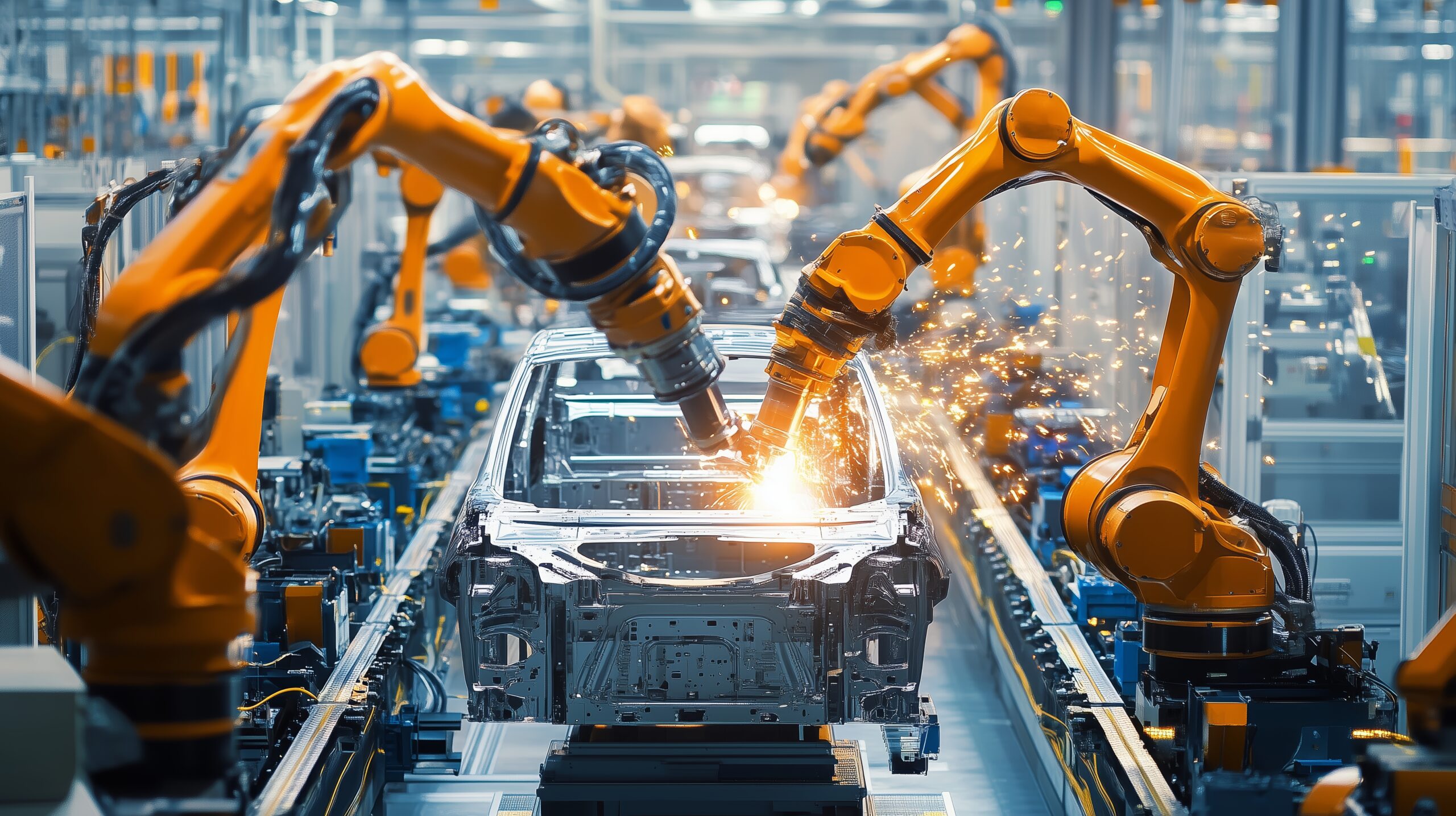

Supported Use Cases

Weld Inspection

- Spatter in Threads

- Location

- Corrosion

- Voids

- Gap

- Spatter in Threads

- Location

- Corrosion

- Voids

- Gap

- Length, Width, Height

- Edge Profile i.e. Radius / Chamfer

- Depth

- Thread Quality

- Length, Width, Height

- Edge Profile i.e. Radius / Chamfer

- Depth

- Thread Quality

Paint Defects

- Color

- Scratches

- Run/Drips

- Blistering

- Dust/Dirt/Contamination

- Wrinkles

- Cracks

Molding Defects

- Flashing / Burrs / Sprue

- Short Shot

- Scratches

- Deformation / Warping

- Dimensional

- Voids / Inclusions

Assembly Verification

- Correct Order and Verification

- Defects

- Misplaces or Missing Parts

- Fill Levels

- Presence / Orientation / Alignment

Product Identification

- OCR

- Presence

- Position Check

Sealant / Glue

- Bead

- Placement

- Gaps

Stamping Defects

- Splits

- Cracks

- Missed Punches

- Missed Inserts

- Dents

- Trim Edge

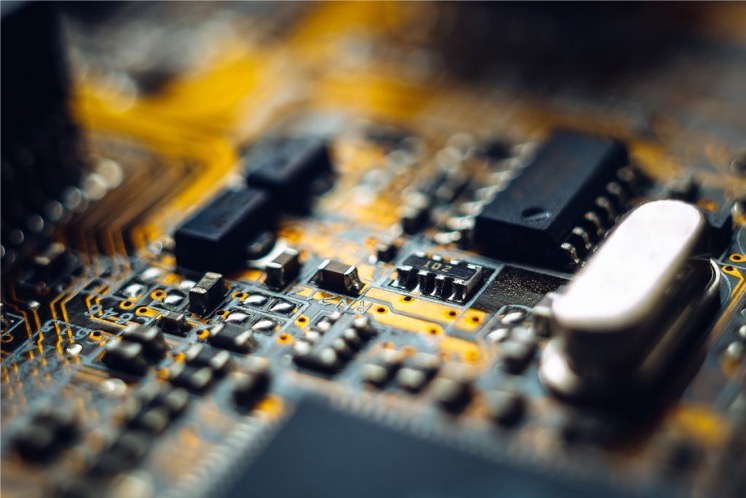

Electronics

- Correct Component

- Component Orientation

- BGA

- Connector Engagement

- Solder Joints

- Damaged Traces / PAds

- Board Cracks / Scratches

- Solder Bridge

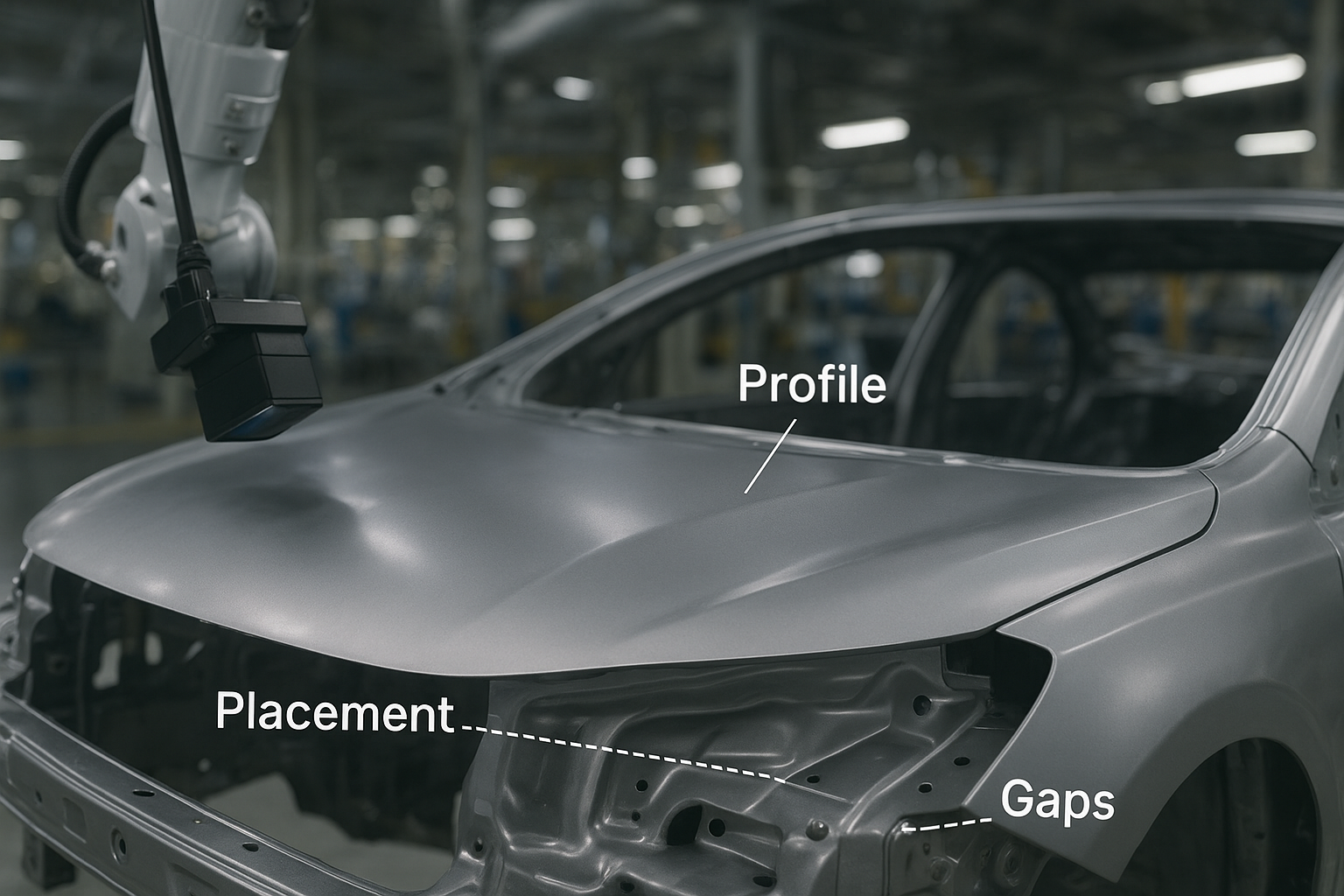

Joining Material

- Profile

- Placement

- Gaps

Cleanliness

- Corrosion / Rust

- Residue

Fabric / Leather

- Wrinkles

- Sewing Seams

- Tears

- Embossing