Computer Vision for Manufacturing Defect Detection

Physical AI. Accurate, Adaptable, Scalable.

Why Mindtrace

Mindtrace is an experienced AI technology developer with a deep commitment to smart manufacturing implementation. The Mindtrace Brain-Sense™ AI technology platform delivers 98%+ detection accuracy that virtually eliminates defect escapes, reduces costs and improves productivity. Mindtrace partners with industry leaders to implement our computer vision AI platform, as a fully automated, end-to-end, defect detection solution.

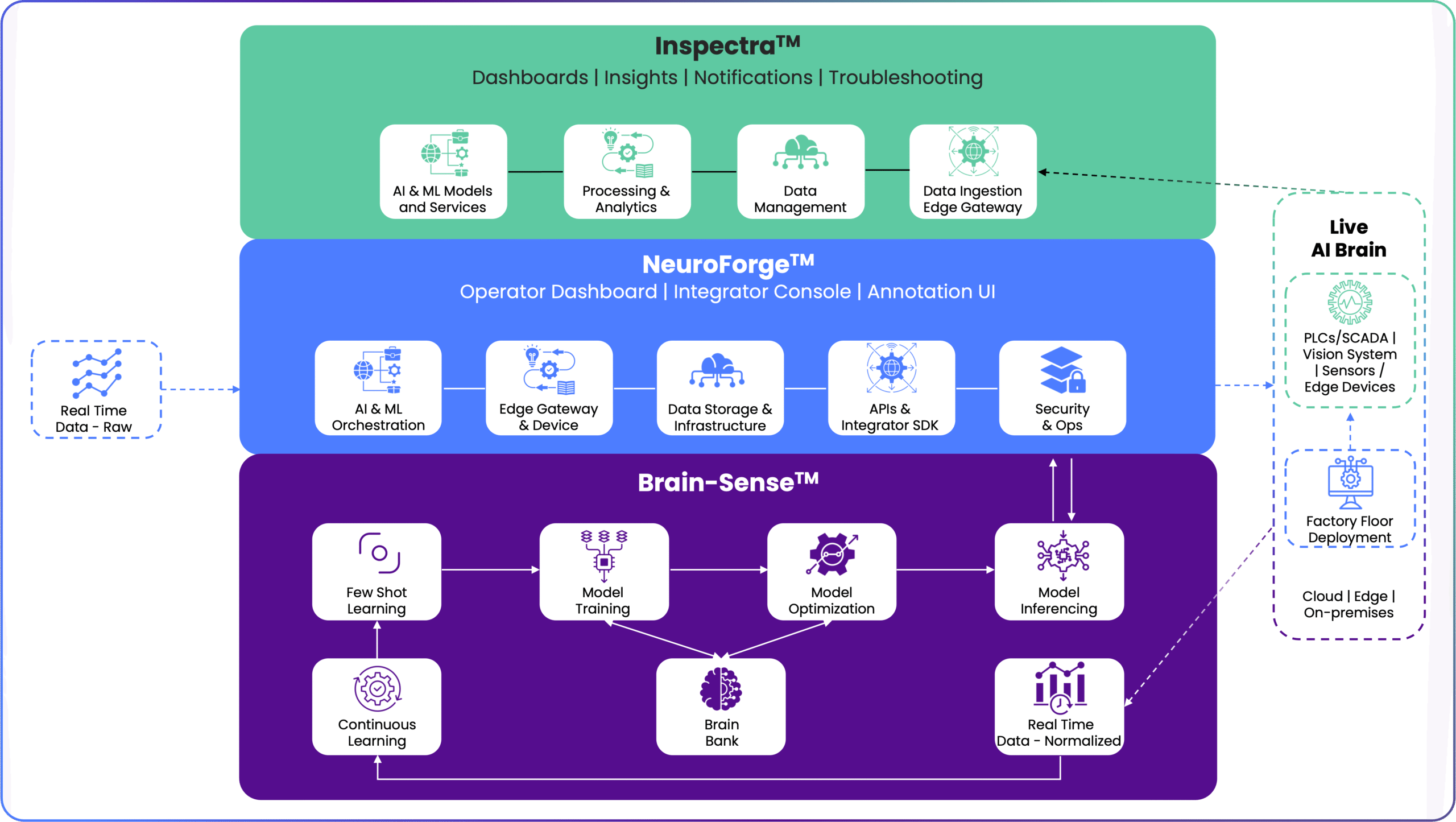

Mindtrace Smart Manufacturing Platform

AI technology is a critical part of Smart Manufacturing automation, but it is not the total solution in itself. This is especially true in manufacturing settings where the technology needs to be integrated into production line equipment, trained to recognize customer-specific defects and provide actionable analytics that drive improvements. Mindtrace understands these requirements and provides a complete smart manufacturing solution that delivers unrivaled accuracy, fast up-times, and lasting value.

Features and Benefits

Immediate Value

- Industry-leading detection accuracy using fewer than 50 training images

Fast Payback

- Average ROI breakeven in 14 months

- Adapts to production process changes and continues to improve with use

Reduced Overhead Costs

- AI automationreplaces the costs and challenges of manual inspection, headcount, training and recruitment

Full Implementation

- End-to-End AI Defect Detection Solution featuring industry-proven AI applications, “best-in-class” automation components, and seamless integration with existing production lines

Versatile & Transparent

- Dashboard manages multiple production lines providing analytics and insights

- Intuitive portal for plant managers and QA experts

Flexible Deployments

- Portal for plant managers and QA experts

- Hardware agnostic AI

- On-prem/Edge/Cloud

Real-Time Answers

- Pass-fail decisions at the speed of production

Affordable

- Computer Vision learning and analytics advantages but with a lower processing power requirement

Advanced Analytics

- Data-driven AI insights identify process improvements across the production line

- Variation analysis supports predictive maintenance to avoid expensive downtimes

How Mindtrace Compares

Mindtrace

Camera Providers

Cloud Platform / Vision Integrators / In-house AI

~20 Images

Thousands

Hundreds – Thousands

Mindtrace

Camera Providers

Cloud Platform / Vision Integrators / In-house AI

Weeks

6 – 18 months

3 – 12 months

Mindtrace

Camera Providers

Cloud Platform / Vision Integrators / In-house AI

Self-learning, continuous

Rigid, retrain from scratch

Manual retraining

Mindtrace

Camera Providers

Cloud Platform / Vision Integrators / In-house AI

Improves with data

Stagnates

Case-by-case

Mindtrace

Camera Providers

Cloud Platform / Vision Integrators / In-house AI

Pre-trained “brains” ~80%

None

None

Mindtrace

Camera Providers

Cloud Platform / Vision Integrators / In-house AI

Low (fewer data + faster)

High (long projects + hardware)

Medium – High

Mindtrace

Camera Providers

Cloud Platform / Vision Integrators / In-house AI

Inception to go-live

Typically, hardware only

None/consulting basis

Mindtrace

Camera Providers

Cloud Platform / Vision Integrators / In-house AI

Agnostic

Locked-in

Agnostic

Mindtrace

Camera Providers

Cloud Platform / Vision Integrators / In-house AI

Adaptive, pre-trained AI

Typically, SDK based

Cloud based, generic model architectures

Use Cases

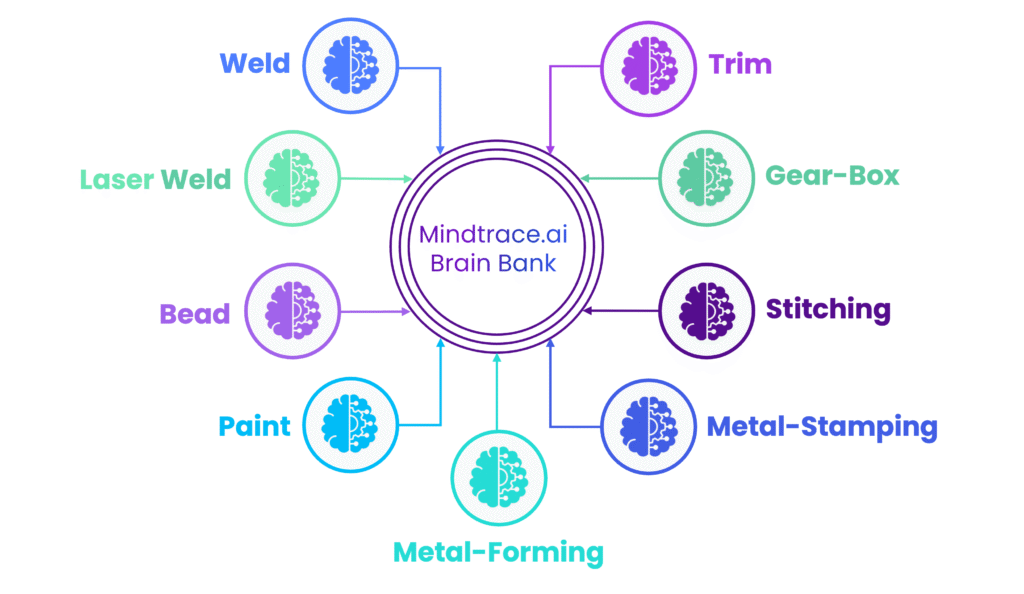

The core of Brain-Sense™ is a Brain Bank of AI data models that are pretrained to recognize a wide range of manufacturing defects. As a result these “brains” can be rapidly customized for each customer’s unique needs with minimal additional.

Use Cases

The core of Brain-Sense™ is a Brain Bank of AI data models that are pretrained to recognize a wide range of manufacturing defects. As a result these “brains” can be rapidly customized for each customer’s unique needs with minimal additional.

Real-World Application

Manufacturing

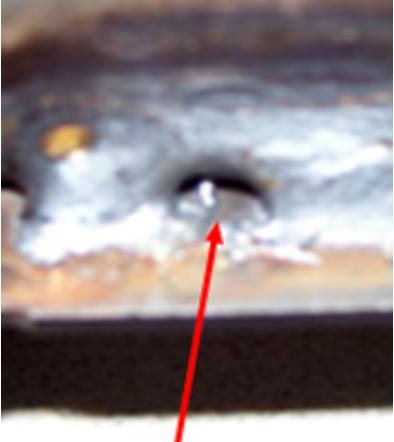

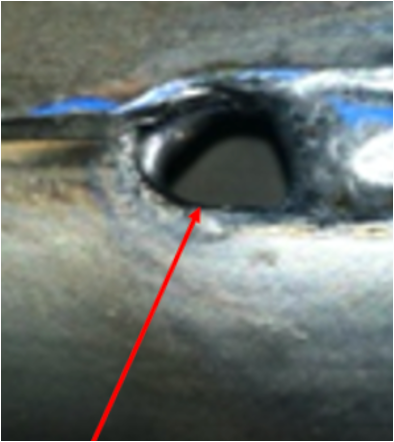

Welding Defects

This project focused on detecting welding defects on automotive seats for a top-tier automotive manufacturer.

Challenges

- 15-40 different welding defect types

- Complex geometries in defective welding joints, varying with configuration

- Limited training data: 10-20 images per defect

Examples

Results

0%

Missed Defects

False Alarm

Gage R&R Score

Other Success Stories

Electronics

Customers & Partners

Frequently Asked Questions

Who is Mindtrace?

Mindtrace is a Vision AI technology company that provides precision manufacturers with an end-to-end defect detection solution that reduces the cost and increases the accuracy of defect detection on high-speed manufacturing lines.

Vision AI is a type of artificial intelligence (AI) that enables computers to analyze and interpret visual information in a way that is like the human brain. It uses machine learning to recognize objects and patterns in images and videos. In manufacturing, Vision AI is used for everything from facial recognition to defect detection.

What is Brain-Sense™

Mindtrace Brain-Sense™ is a proprietary AI technology platform for defect detection that provides precision manufacturers with the learning flexibility of a human brain, without the errors, fatigue and overhead costs of manual inspection teams. The core of Brain-Sense™ is a computer vision database of manufacturing defect use cases or “brains” that learn from the data itself to quickly deliver industry leading detection accuracy that improves with use. Brain-sense™ provides manufacturers with faster pass/fail decisions and uses less processing power than other computer vision platforms, while still delivering faster start-ups and more flexible change management than traditional rules-based, machine vision platforms.

What type of Vision AI does Mindtrace develop?

The Brain-Sense™ AI platform from Mindtrace is a proprietary Computer Vision AI technology that uses image-based learning to reduce training time and adapt to future process changes better than rule-based Machine Learning AI technology. Mindtrace provides parts manufacturers with a defect detection capability that learns quickly and continuously, adapts to changes, makes real-time “pass-fail” decisions but requires much lower investment in processing power than most other Computer Vision platforms.

Why do I need Mindtrace now?

Trends like Industry 4.0 are driving manufacturers to reduce costs, increase productivity and embrace quality improvement concepts like Zero Defect Manufacturing (ZDM).

Human inspection teams are costly to recruit and train, and the repetitive nature of the work makes them prone to fatigue, turnover and errors. Research indicates that manual manufacturing defect detection can have error rates of 20% to 30%. These errors can mean additional costs in waste, returns and loss of reputation.

Replacing human inspectors with an AI technology solution reduces overhead costs and can improve defect detection accuracy to 90% or more.

Does Mindtrace provide a fully implemented solution?

Yes. A fully automated AI defect detection solution includes HD imaging equipment and lighting systems to capture the images on the production line, AI software to interpret and make decisions about the images, robotic equipment to remove defects, and an implementation team to install the system, provide training, tech support and O&M services.

As a premier Vision AI technology developer Mindtrace has built a network of industry leading strategic partners including Paslin, to provide the equipment and implementation.

Does Brain-Sense™ offer flexible implementation?

Brain-Sense™ can be implemented in a variety of ways including as a stand-alone SaaS platform, or on-premises as part of the end-to-end total™ solution. Based on the preference our manufacturing customers the Brain-Sense™ technology platform may be invoiced as a recurring licensing fee or bundled into the end-to-end deployment as a one-time cap-X payment

Does Mindtrace have manufacturing expertise?

Yes. Most recently, Mindtrace was engaged by Adient, a global leader in automotive seating systems with 200+ plants in 29 countries. Their manual defect detection process was producing inconsistent, inaccurate results and causing a bottle neck in the production line.

In just over 12 weeks and using an average of 10 training images per error type, Mindtrace implemented an automated, 24/7, end-to-end AI defect detection solution that eliminated inconsistencies, improved defect detection accuracy to 95+%, and sped up cycle time by 80%.

These results impressed the company enough to authorize Mindtrace to work with their other factories and announce in its FY 2024 Earnings call that it had become an investor.

What is the bottom line for manufacturers?

Mindtrace develops defect detection AI technology that enables precision manufacturers to reduce the cost and improve the accuracy of defect detection on high-speed production lines. Our Computer Vision technology learns faster and is more flexible than rule-based, Machine Vision systems, but makes decisions faster and requires a lower processor power investment than other Computer Vision platforms. Together with industry leading providers, we offer this technology as a turnkey end-to-end automated solution, and provide deal structures that meet the product and purchasing requirements of our customers.