Mindtrace Inspectra™

Trends & Actionable Insight

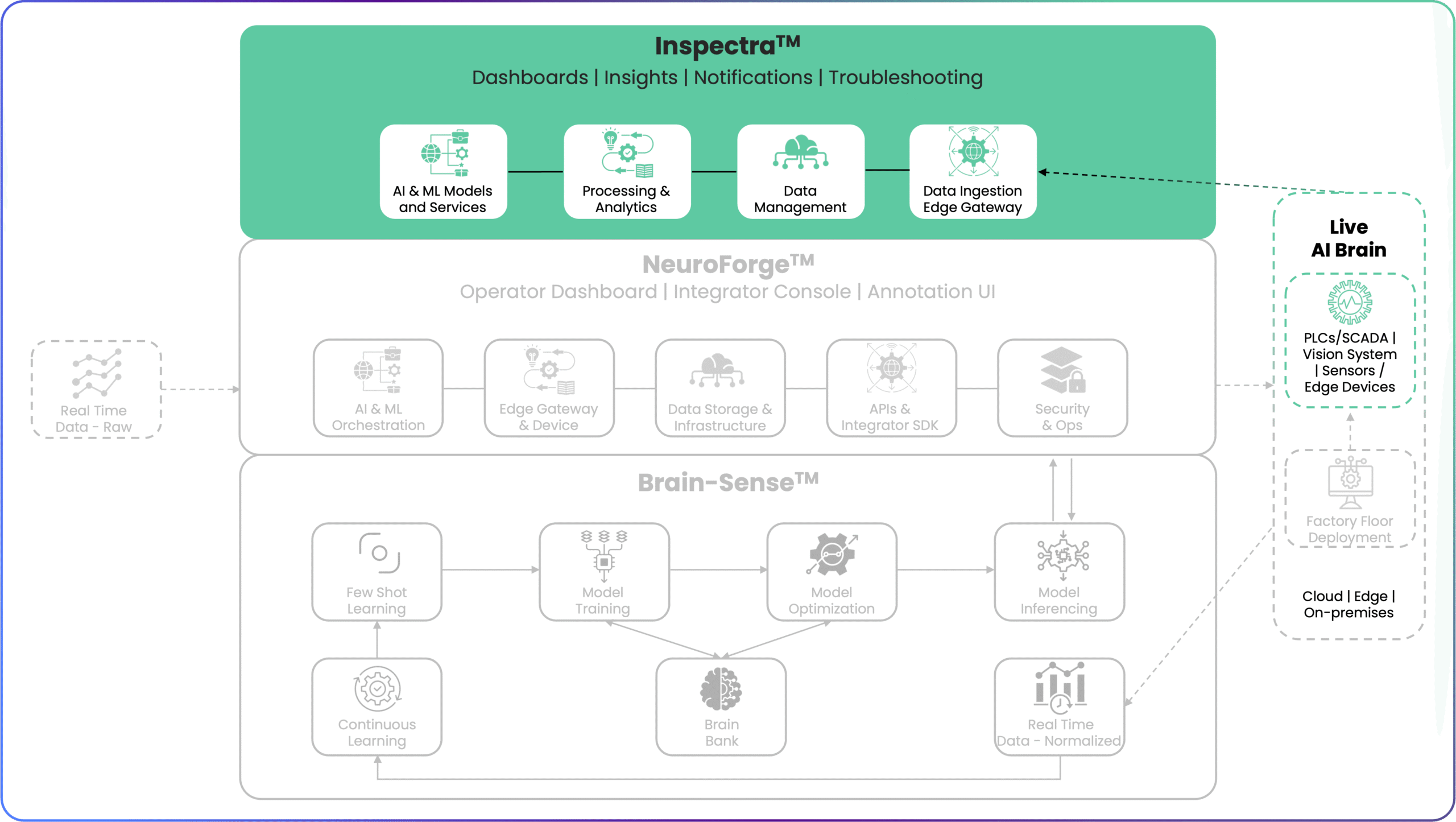

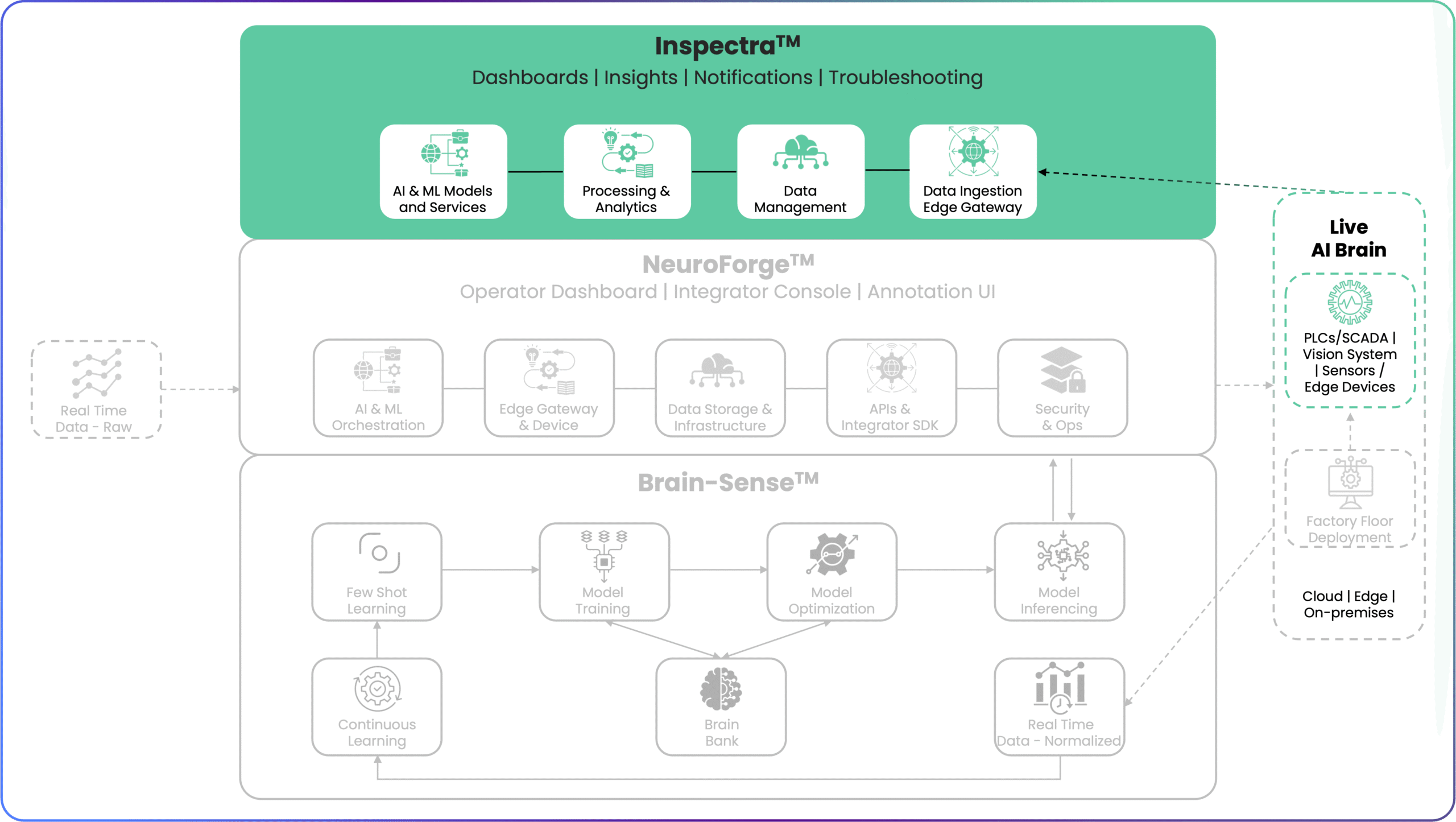

Inspectra™ is a powerful analytics portal that synchronizes with the “AI Brains” deployed by NeuroForge™, to collect, catalog, and analyze defect data on the factory floor. Inspectra™ delivers:

- Predictive analytics

- Root cause analysis

- Compliance reporting

- Monitoring & insights

Inspectra™ turns parts inspection data into actionable intelligence that empowers OEMs and suppliers with transparent, auditable insights that improve quality, compliance, and customer trust.

Mindtrace Inspectra™

Trends & Actionable Insight

Inspectra™ is a powerful analytics portal that synchronizes with the “AI Brains” deployed by NeuroForge™, to collect, catalog, and analyze defect data on the factory floor. Inspectra™ delivers:

Inspectra™ turns parts inspection data into actionable intelligence that empowers OEMs and suppliers with transparent, auditable insights that improve quality, compliance, and customer trust.

With Mindtrace

Fewer Images

Cost Reduction

Gage R&R Score

With Mindtrace

Fewer Images

Cost Reduction

Gage R&R Score