Mindtrace.ai Launches two Industrial AI Applications that Transform Automated Inspection in Precision Manufacturing

NeuroForge™ is a fully automated parts quality inspection solution that seamlessly integrates to manufacturing automation and enterprise legacy systems

Inspectra™ extends NeuroForge™ capabilities, for defect trend visibility, auditability and predictive analytics for multi-lines and multi-locations

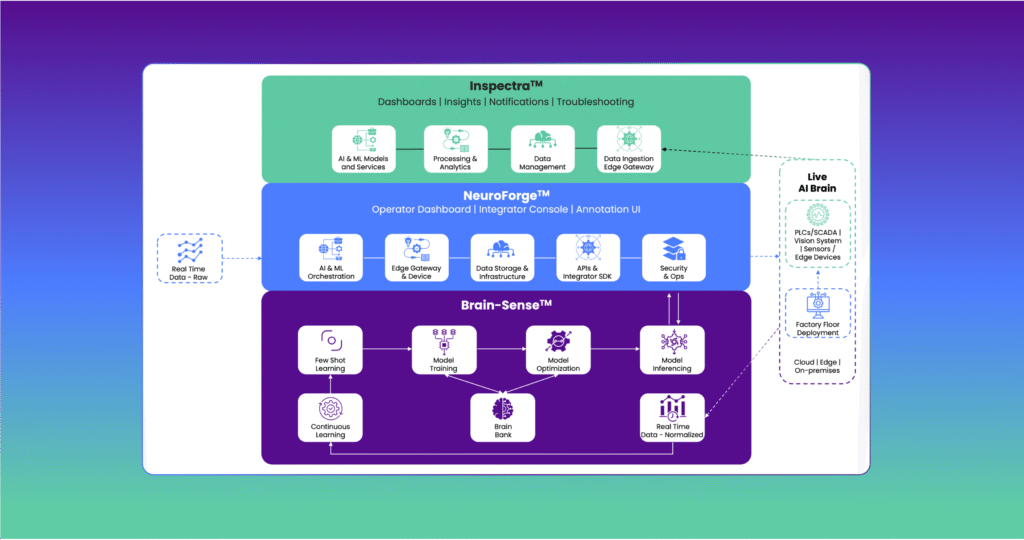

Detroit, Michigan – October 29, 2025 – Mindtrace.ai, a leading provider of artificial intelligence for automating the detection of manufacturing defects for weld, surface flaws, part presence/identification/measurement, metal stamping, and other automotive use-cases, today announced the commercial launch of NeuroForge™ and Inspectra™, two technology applications that build-on and enhance the capabilities of Brain-Sense™, the company’s proprietary computer vision AI technology platform.

NeuroForge™ is an enterprise AI software that leverages the pre-optimized AI models and neural representations from the Brain-Sense™ AI platform. Key advantage is fast deployment of physical AI solutions to exceed enterprises’ performance requirements unique to customers’ specific use cases and operating environment. This physical AI application is far superior to conventional one-size-fits-all ML offerings that often get mothballed after long painful deployment primarily due to inaccuracies and inability to adapt to changes.

NeuroForge™ enables enterprise users to easily finetune, standardize, and scale defect detection solution to multiple production lines throughout the enterprise. NeuroForge™, with built-in tools, integration APIs, and automation hooks, enables enterprises and integrators to easily integrate “end-to-end“ solutions into new or legacy factory floor systems resulting in faster time to value.

Inspectra™ is an analytics application that digitizes all defect detection data into one repository that can be mined for insights, performance improvements, and preventive measures. InspectraTM analyzes serial number specific results to identify trends and provide root cause analysis.

“Mindtrace constantly monitors the AI landscape, latest innovations in the field of AI Engineering, and continue to enhance the Brain-Sense™ platform to provide our manufacturing customers with physical AI solutions that deliver ROI and continuous performance improvements. “Delivering a worldclass AI solutions for select enterprise customers and partners is our mission,” said Hoon Chung, CEO of Mindtrace. “Our unique value is being a trusted partner for enterprise customers through flawless delivery and execution in support of our clients’ constant pursuit of competitive edge, cost efficiency and digital resiliency.”

Technology advancements and competitive pressures are pushing manufacturers to integrate artificial intelligence and other smart manufacturing capabilities into their production automation systems. Citing the Rockwell Automation 2025 Annual State of Smart Manufacturing Report, “Quality is a practical AI use case right now and key to business operations and strategy. Half of respondents plan to use Artificial Intelligence/Machine Learning to support quality control in the next 12 months, and 38% will use data collected from current sources to drive product quality monitoring and improvements. Globally, 43% of respondents said product quality/safety mattered most to their sustainability program.”

Brain-Sense™ features a computer vision AI technology that requires fewer than 20 reference images to rapidly teach itself to recognize defects with industry leading accuracy. It can also automatically adapt its interpretation of defects when changes are introduced to the production environment. These capabilities result in much faster implementation cycles and lower change costs than rule-based AI technologies that can require thousands of images and system resets when presented with the same issues.

“Mindtrace is not only trailblazing the transformation of smart manufacturing with its AI Brain-Sense™ Platform but also ensuring that innovation reaches the factory floor through NeuroForge™ integration and Inspectra™ analytics. Together, these technologies are delivering stunning results in accuracy, productivity, and cost-efficiency. What excites me most is the overwhelmingly positive feedback we’re hearing from customers,” Sir Hossein Yassaie, Technology Entrepreneur and Chairman of Mindtrace.ai.

About Mindtrace.ai

Mindtrace develops AI technology that is integrated into the automation equipment of industry leading automation companies, to provide precision manufacturers with an end-to-end defect detection solution. Mindtrace’s Brain-Sense™ Computer Vision technology platform delivers 98%+ detection accuracy that virtually eliminates defect escapes, reduces costs and improves productivity. Mindtrace was founded in 2017 and is headquartered in Manchester, United Kingdom with U.S. offices in Michigan and California.

Contact:

Jessica Ungerer

jessica@mindtrace.ai