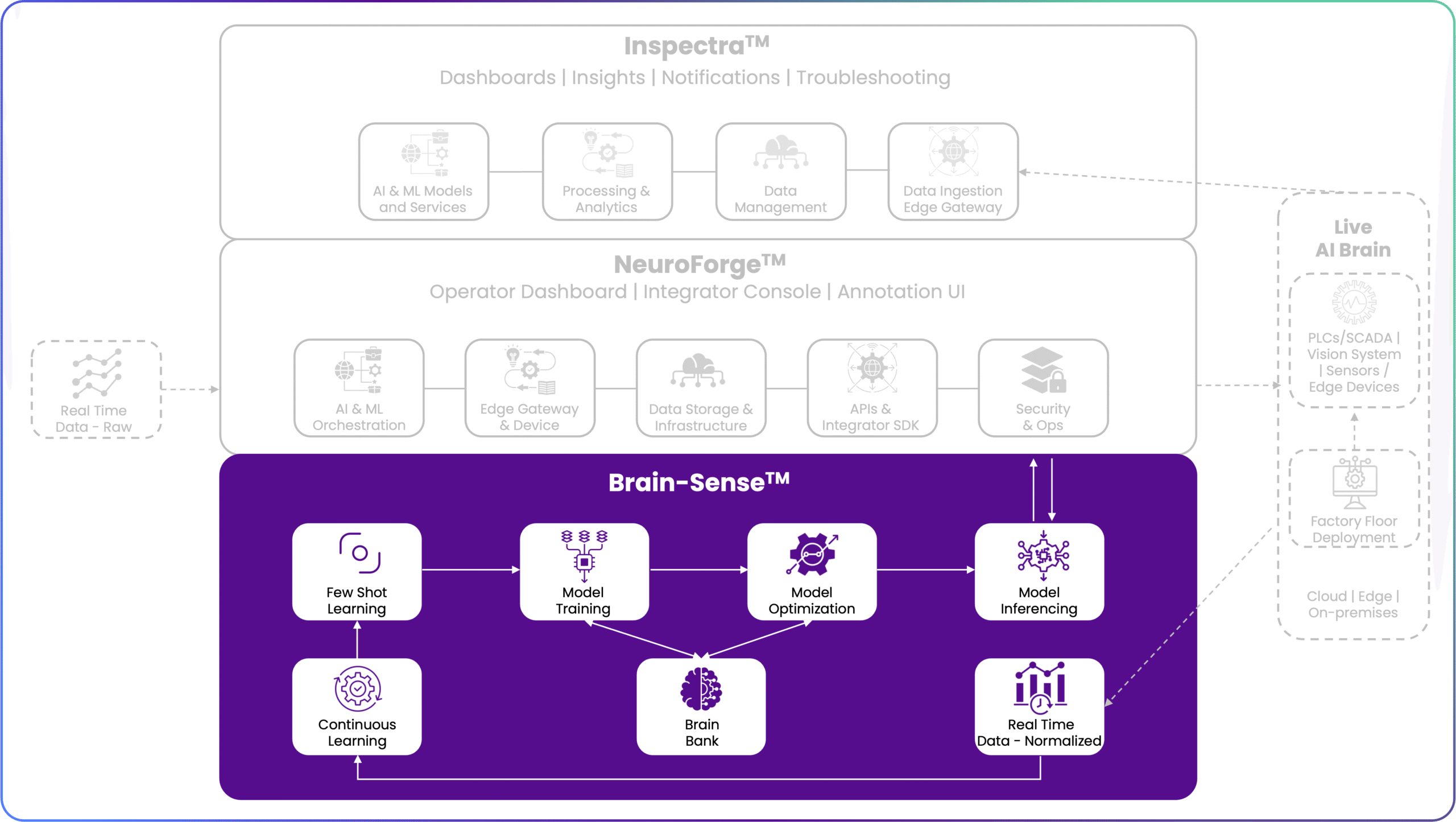

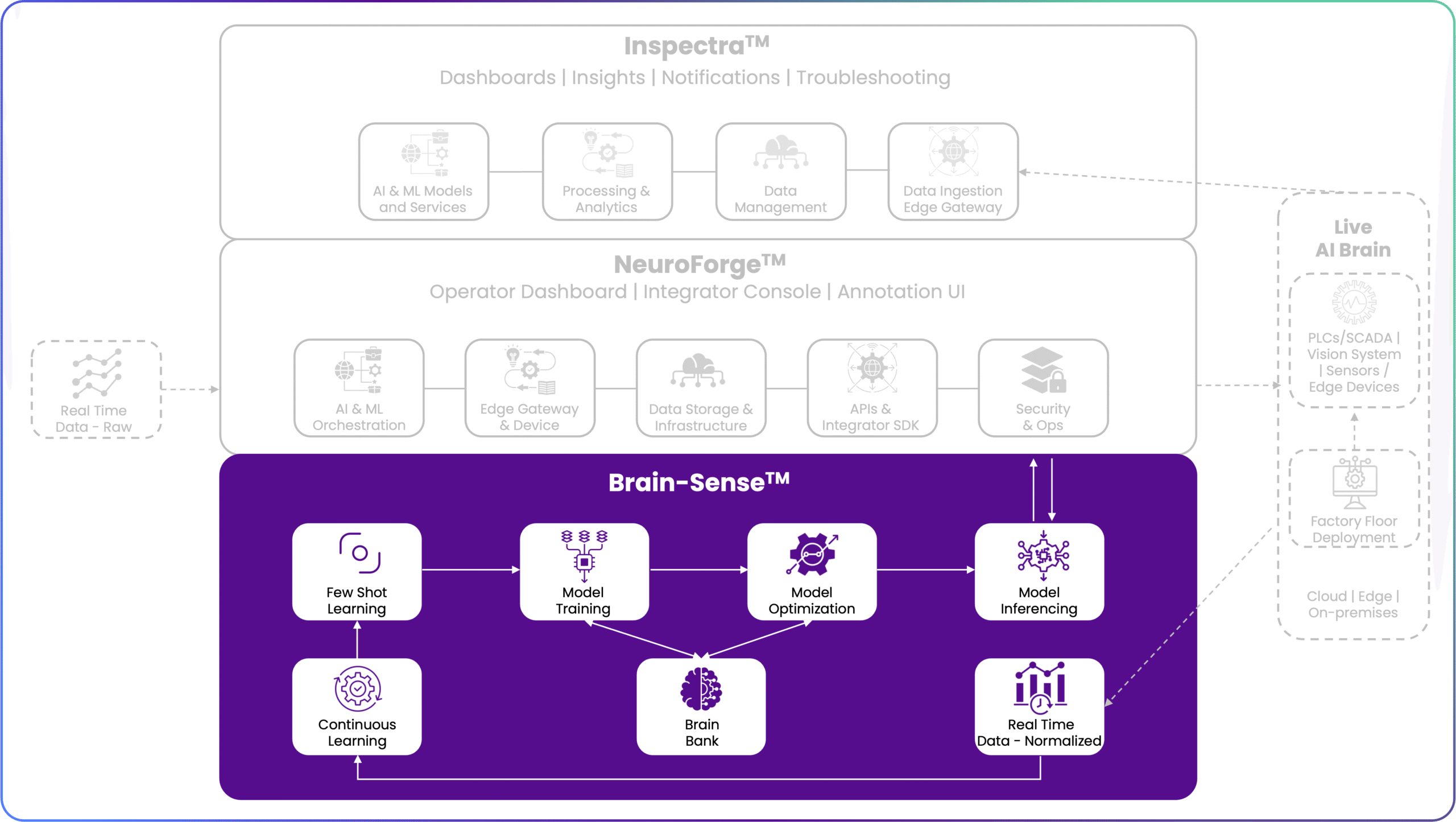

Brain-Sense™ Technology Platform

Computer Vision for Defect Detection

Brain-Sense™ is the proprietary Mindtrace AI platform for manufacturing defect detection. It provides manufacturers with fully automated, highly accurate, defect detection with significant advantages:

- Detects defects faster and more accurately, reducing escapes and improving yield

- Operates 24/7/365 without fatigue

- Delivers cost savings compared to manual inspections

Brain-Sense™ Technology Platform

Computer Vision for Defect Detection

Brain-Sense™ is the proprietary Mindtrace AI platform for manufacturing defect detection. It provides manufacturers with fully automated, highly accurate, defect detection with significant advantages:

- Detects defects faster and more accurately, reducing escapes and improving yield

- Operates 24/7/365 without fatigue

- Delivers cost savings compared to manual inspections

With Mindtrace

Fewer Images

Cost Reduction

Gage R&R Score

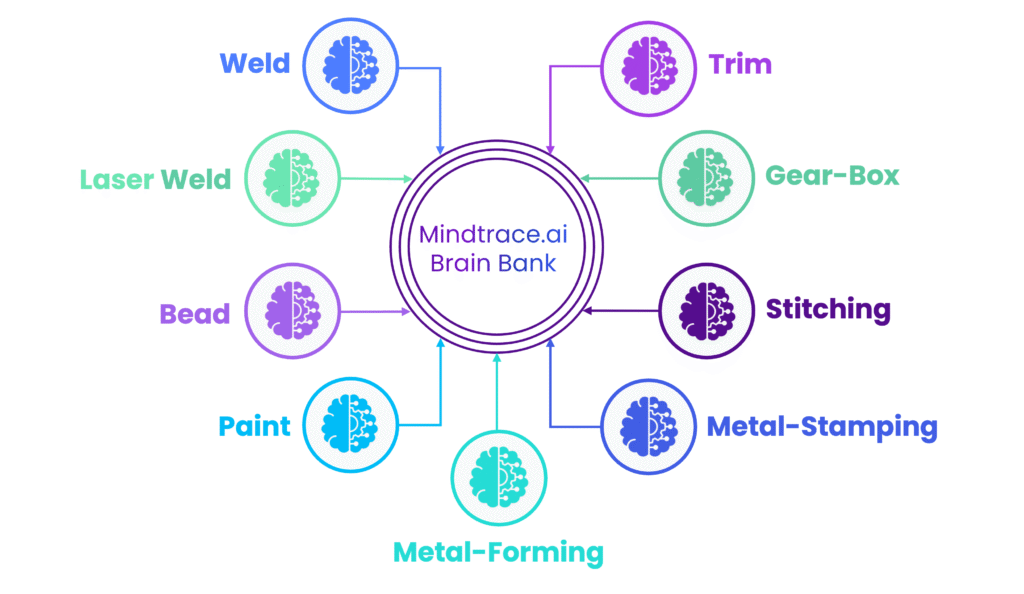

Brain-Sense™ AI Brain Bank

The core of Brain-Sense™ is a Brain Bank of AI data models that are pretrained to recognize a wide range of manufacturing defects. As a result these “brains” can be rapidly customized for each customer’s unique needs with minimal additional.

The Brain-sense™ platform provides manufacturers with rapid pass/fail decisions and uses less processing power than other computer vision platforms, while still delivering faster start-ups and more flexible change management than traditional rules-based, machine vision platforms.

Key Capabilities of Brain-Sense™

Brain-Sense™ incorporates powerful, proven AI techniques into a unified, practical platform for manufacturing defect detection.

Fast & Efficient Training

- Few-Shot Detection – Achieves high accuracy with as few as 20 images, minimizing data collection and training time.

- Transfer Learning – Adapts pre-trained AI “brains” to new tasks quickly, accelerating deployment.

Smarter Over Time

- Continuous Learning – Models adapt to new parts, processes, and defects without retraining from scratch.

- Self-Supervised Learning – Improves performance using unlabelled data, reducing reliance on expensive annotations.

Deeper Quality Insights

- Unsupervised Learning – Detects hidden patterns and insights beyond predefined rules.

- Deep Attention Learning – Focuses on the most relevant features of each part, improving accuracy and defect recognition.

Fast & Efficient Training

- Few-Shot Detection – Achieves high accuracy with as few as 20 images, minimizing data collection and training time.

- Transfer Learning – Adapts pre-trained AI “brains” to new tasks quickly, accelerating deployment.

Fast & Efficient Training

- Few-Shot Detection – Achieves high accuracy with as few as 20 images, minimizing data collection and training time.

- Transfer Learning – Adapts pre-trained AI “brains” to new tasks quickly, accelerating deployment.

Smarter Over Time

- Continuous Learning – Models adapt to new parts, processes, and defects without retraining from scratch.

- Self-Supervised Learning – Improves performance using unlabelled data, reducing reliance on expensive annotations.

Smarter Over Time

- Continuous Learning – Models adapt to new parts, processes, and defects without retraining from scratch.

- Self-Supervised Learning – Improves performance using unlabelled data, reducing reliance on expensive annotations.

Deeper Quality Insights

- Unsupervised Learning – Detects hidden patterns and insights beyond predefined rules.

- Deep Attention Learning – Focuses on the most relevant features of each part, improving accuracy and defect recognition.

Deeper Quality Insights

- Unsupervised Learning – Detects hidden patterns and insights beyond predefined rules.

- Deep Attention Learning – Focuses on the most relevant features of each part, improving accuracy and defect recognition.